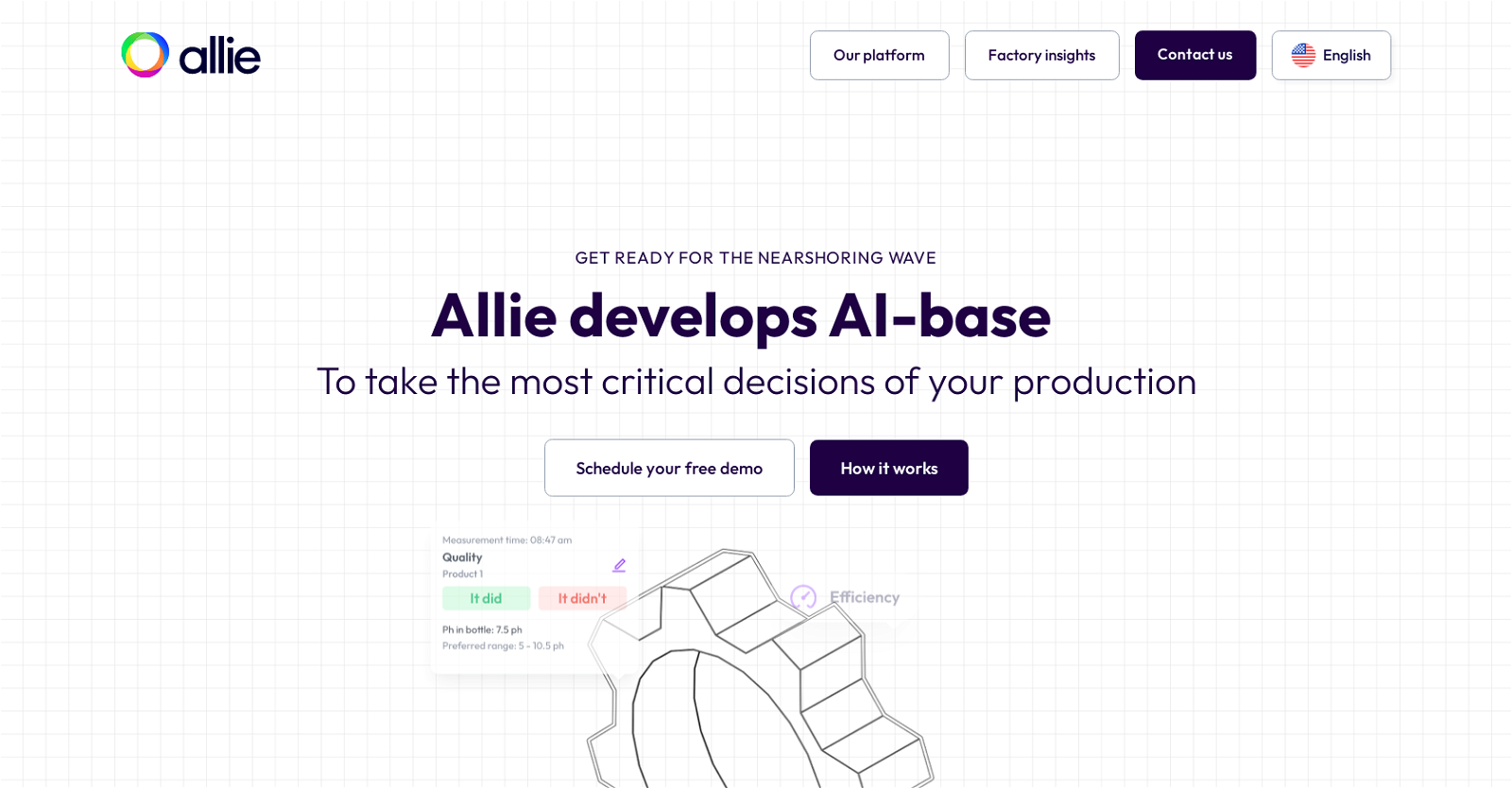

Allie is an AI-based maintenance and efficiency software that aims to boost factory performance. It offers a range of features including digitized production lines, real-time alerts, asset monitoring, and predictive failure analysis to improve operational efficiency.

By digitizing and monitoring production processes in real-time, Allie helps reduce downtime, allowing factories to achieve more efficient results with the same resources. It also helps in reducing operating costs by automating labor-intensive tasks and analyzing relevant variables, leading to increased efficiency.

The software facilitates productivity enhancement by setting and achieving competitive targets, contributing to the growth and profitability of the factory. Allie ensures interconnectivity between systems by using plug-and-play solutions that easily connect with ERP systems, consolidating data into a single source.

Allie offers several functionalities, including machine connectivity through a mobile app, predictive maintenance using machine learning algorithms, and automation of preventive and corrective maintenance flows. The software also provides multi-device adaptability, ensuring ease of use and prompt response on a daily basis.

Allie’s impact is demonstrated by numerous machines connected, downtime hours saved, and an average increase in productivity. It is widely used across industries such as steel, construction, chemical and pharmaceutical, food and drinks, textiles, mining, plastics and paper, and agriculture.

With its technical assessment, deployment, and activation processes, Allie simplifies the implementation of transformative changes in production lines. The software is backed by leading companies and offers a free demo to interested users.